Our Services

Air-Conditioning

Once we understand the requirement of a client, the first step for us is to perform heat load calculations to identify the cooling capacity and airflow required to keep the given space at desired temperature and relative humidity. We can make manual calculations however we use the latest tools like E-20 and Carrier’s HAP software. We strictly comply with local, federal, and international standards (ASHRAE/Green Building Regulations) while performing thermal load calculations.

Air distribution systems play a pivotal role in a central air-conditioning system. AWCT, with its expertise, can design Air Distribution Systems using VRM, EFM and SRM as per the requirements of each project. Relevant codes and standards like SMACNA and DW144 are complied during this exercise. McQuay DUCTSIZER software is also used by us for sizing round, square and rectangular ducts.

Chiller selection and pump head calculation is also done by us in a professional way. Pipe sizing is carried out by us using the industry renowned McQuay PIPESIZE software.

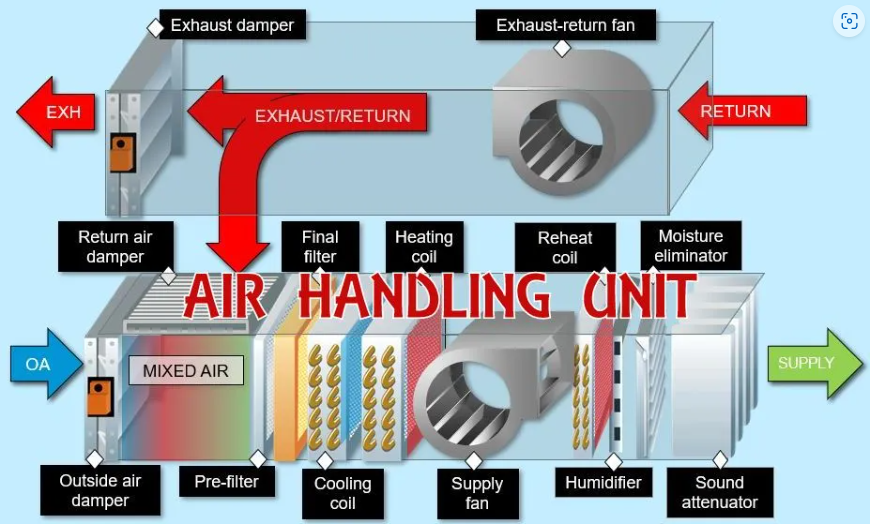

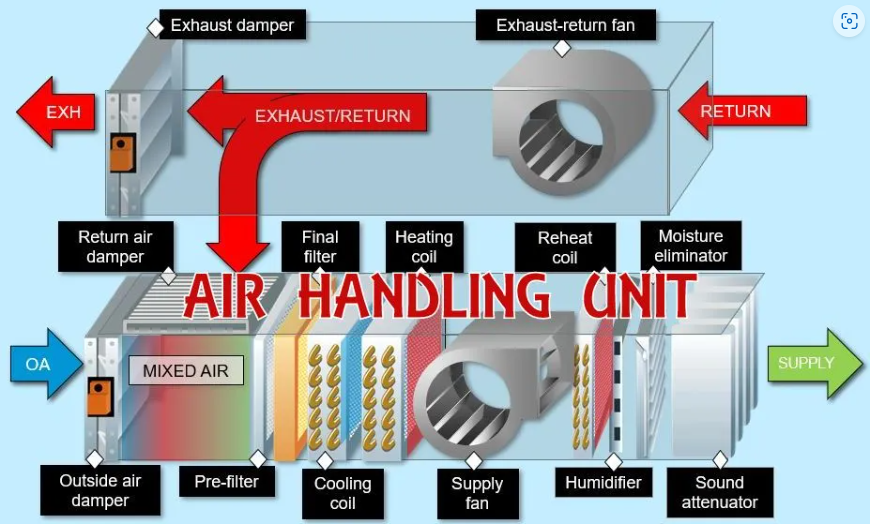

Equipment selection is something which will decide the fate of the designed system. No matter whether it is an AHU/FAHU or any type of evaporating unit, we design coils and select them in a way that the desired temperature and relative humidity is achieved. Not only that, but we also cautiously calculate the External Static Pressure of a fan so that it can deliver the required volume of air smoothly. The same is the case with pump selection (i.e., Pump Head Calculation) for Chilled Water Systems.

For a central air conditioning system with a chiller, in addition to performing manual calculations for pipe sizing, we use McQuay’s PIPESIZER software.

We carry out cost estimation of the entire project to make the client understand the resources required to accomplish the task.

*Industry renowned software (E-20/HAP/McQuay DUCTSIZER/McQuay PIPESIZER) are used by AWCT*

Cooling Tower

A central air conditioning system with a water-cooled chiller must be accompanied by a Cooling Tower. Large field-erected cooling towers are required in District Cooling Plants. We give great importance to Cooling Towers as they dissipate heat from the system and if the heat is not rejected properly then it will affect the performance of the Chillers.

We design cooling towers for new projects, be it for HVAC or Industrial application. Thermal upgradation of existing cooling towers is one of our interesting tasks.

We help our clients choose the right fill (heat exchanger) and other accessories like drift eliminators, air inlet louvers and nozzles for their cooling towers so that they meet the design criteria. We also help our clients with issues like clogging, fouling, drift loss and water splashing out to name a few. Our advice helps our customers in improving their existing systems.

Ventilation

One of our specialties is designing Kitchen Ventilation Systems (for residences/restaurants/hotels/hospitals) with customized multi-stage Ecology Units. Our systems not only exhaust the air from the kitchen with the help of Exhaust Air Fans selected with great care, but also remove/reduce impurities like oil, grease, dust particles, smoke, and odor present in the exhaust air. Treated fresh air supply can be provided in the Kitchen Hood by using innovative methods to minimize the electric power input and maximize the productivity of the Kitchen by providing comfortable work environment to the Chef. Air distribution systems designed by us offer low external static pressure thereby reducing the power consumption of the whole HVAC system.

Refrigeration

Preservation of perishable food is essential to meet the increasing demand and is only possible by having accurately designed cold storages, cold rooms, and refrigerated display cabinets.

AWCT provides excellent support to its clients at every stage of a Refrigeration Project i.e., from concept till completion irrespective of the size of the project.